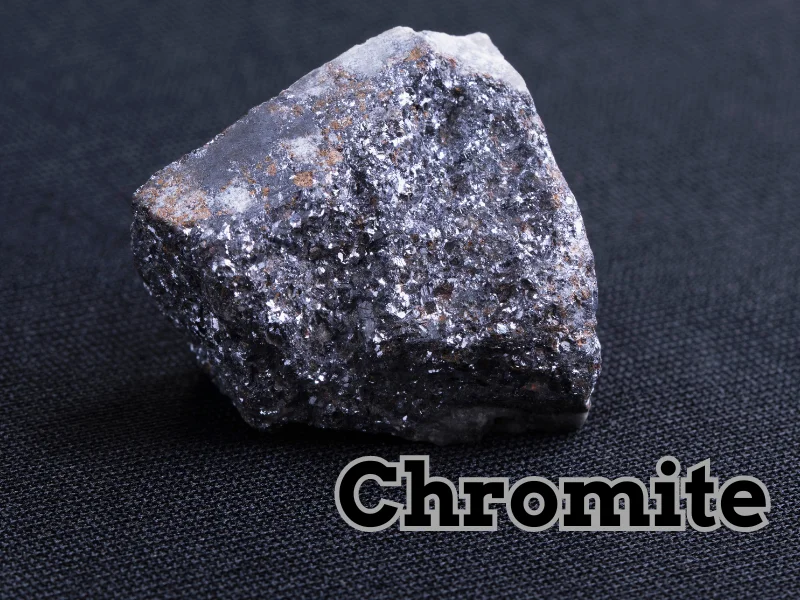

Chromite is the primary ore of chromium, an essential element used in various industrial applications, including stainless steel production, alloy manufacturing, and in the chemical industry.

Testing and analysis of chromite ore are crucial to determine its suitability for these applications and to ensure its quality and efficiency during processing. Below is a description of the key testing and analysis methods for chromite.