Alternative for River Sand

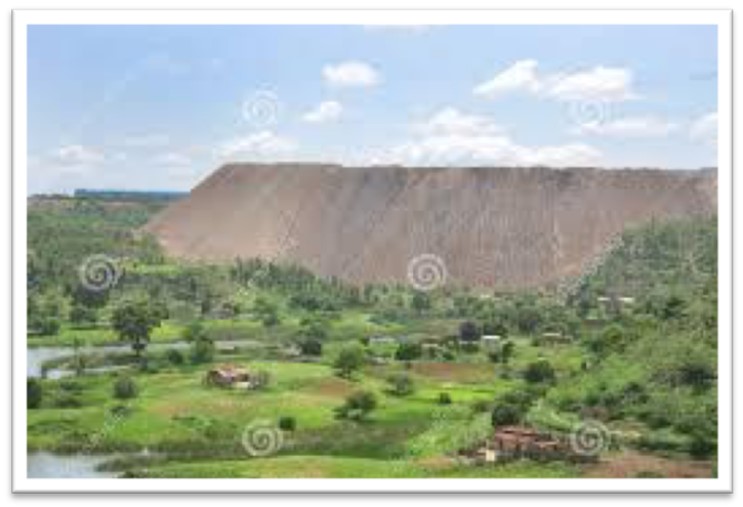

- Overburden is the material that lies above the coal seams, consisting of soil, rock, and other materials.

- In surface mining, overburden must be removed to access the coal underneath.

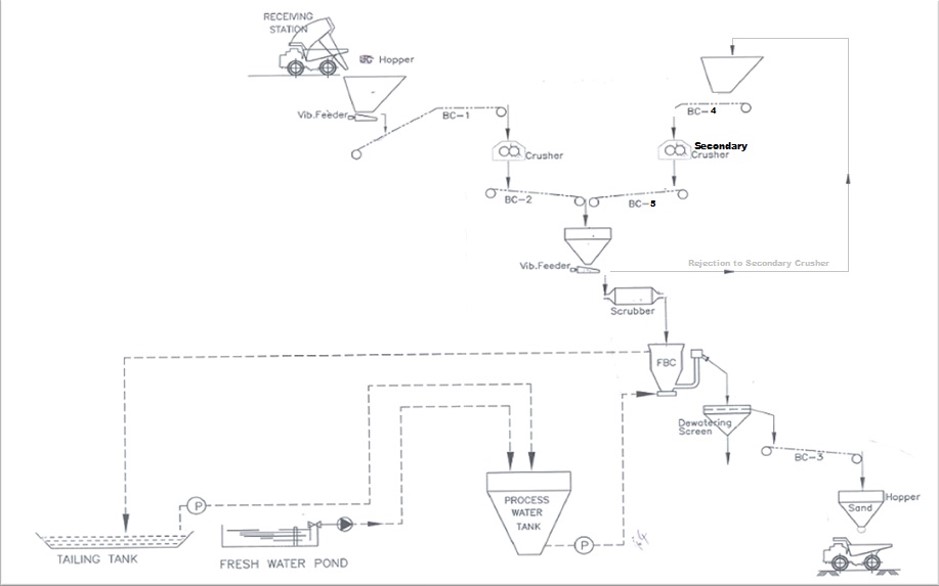

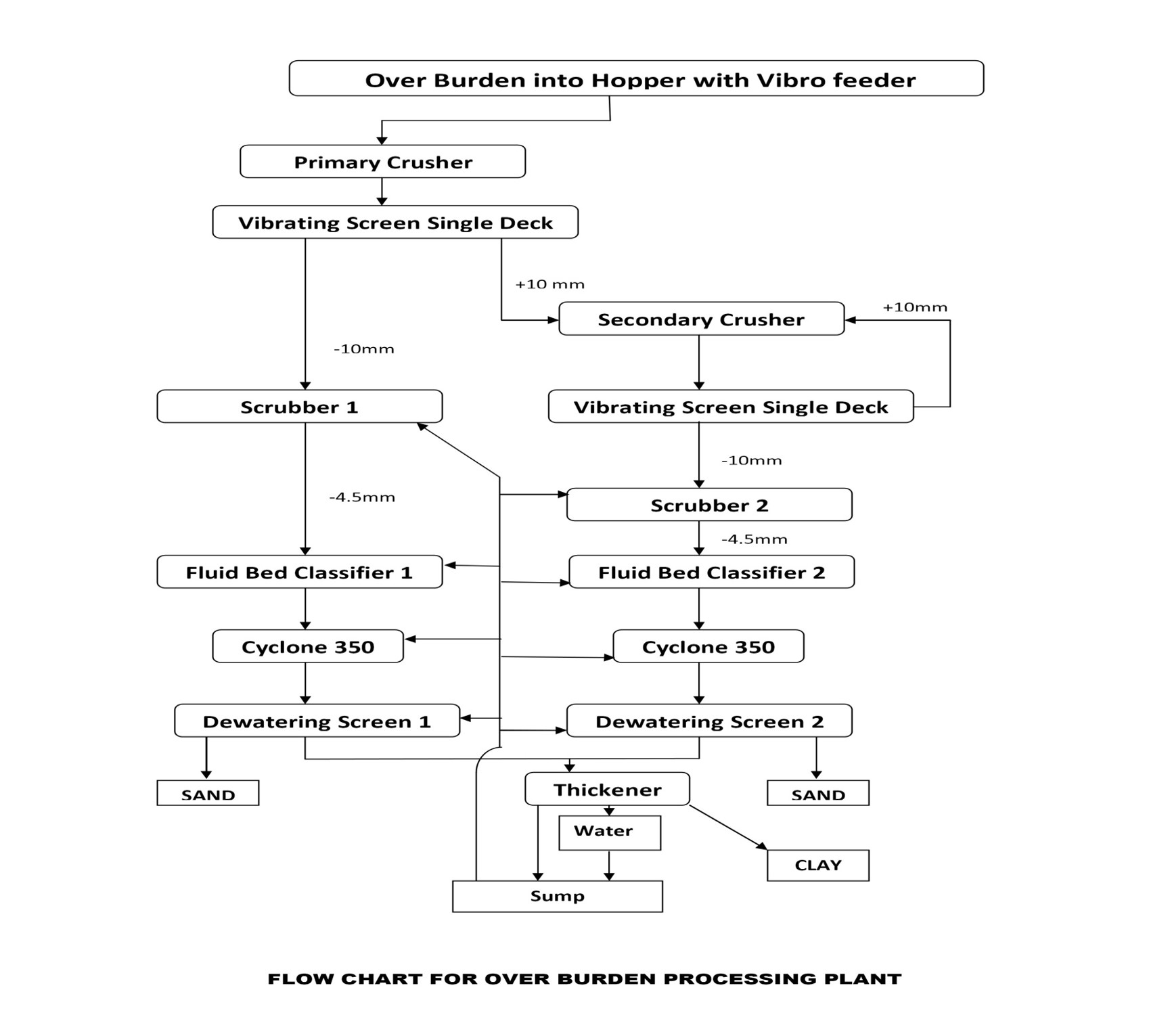

- Removing overburden during coal mining creates a large amount of waste material that can be repurposed.

- Processing this overburden allows for the recovery of sand, which can be used as an alternative to river sand.

- The recovered sand is comparable in quality to sand mined from rivers, making it a sustainable option.

- Utilizing overburden for sand production helps to reduce environmental impacts caused by river sand mining.